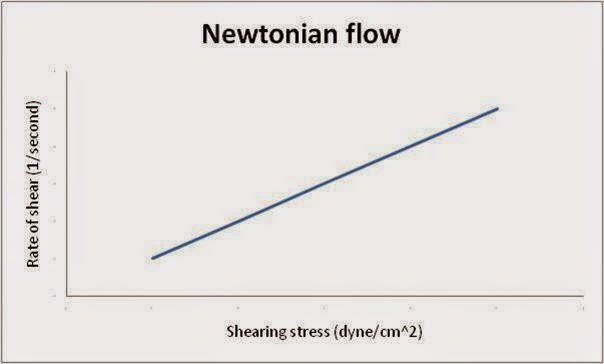

Simple liquids such as water, glycerin, and olive oil follow Newton's law of flow. In such fluids, the relationship between rate of shear and shearing stress is linear. The slope of the plotted line of rate of shear vs. shearing stress is equal to fluidity (1/viscosity) as shown in the following plot.

Systems that have flow behavior that does not follow Newton's law of flow are non-Newtonian. These are more complex systems such as colloidal solutions, emulsions, creams, pastes, and gels. Non-Newtonian flow includes the following types:

- Plastic flow (Bingham body).

Materials that are plastic in their flow behavior do not flow until the shearing stress reaches a certain point called yield value. After initiation of flow the viscosity (plastic viscosity) remains constant as shearing stress increases.

- Pseudoplastic flow.

Materials that follow this flow behavior flow at the smallest applied shearing stress. However, their apparent viscosity decreases as shearing stress increases. Therefore, such flow behavior is known as shear thinning.

- Dilatant flow.

Materials with such flow behavior tend to increase their resistance to flow (apparent viscosity) as shearing stress increases. This is due to entrapment of air bubbles during application of shearing stress (e.g. mixing). The entrapped bubbles increase friction inside the material and therefore increase viscosity. The entrapped air leads to total increase in the volume (dilatant) and reduction in density.

No comments:

Post a Comment

Thank you for your comment.